The Circular Chain of Upcycling

Click any material below to see how it is transformed through our recycling process.

Fabric Recycling

→

→

→

→

Fabric recycling begins with the collection of old clothes and textile waste from donation bins, households, or factories. The items are then sorted based on material type (e.g., cotton, polyester, wool). Usable clothing is sent for resale, while worn-out or unusable items move forward to recycling.

Natural fibers like cotton and wool are shredded and respun into yarn or turned into insulation, stuffing, or cleaning cloths. Synthetic fibers like polyester are shredded and melted into plastic pellets to be reused in new garments. Some advanced methods even chemically break down fabrics into raw materials. This process helps reduce landfill waste and encourages a circular fashion economy.

Recyled fabrics

Wood Recycling

→

→

→

→

Wood waste from construction, furniture, or demolition sites is collected and sorted. Clean, untreated wood can often be reused directly. The rest is processed after removing nails, screws, and paint.

Recyclable wood is shredded or chipped into mulch, wood chips, or sawdust. These materials are then used to make particleboard, medium-density fiberboard (MDF), or compost, and can even serve as biofuel. Recycling wood preserves natural forests and reduces landfill pressure.

Recycled Wood materials

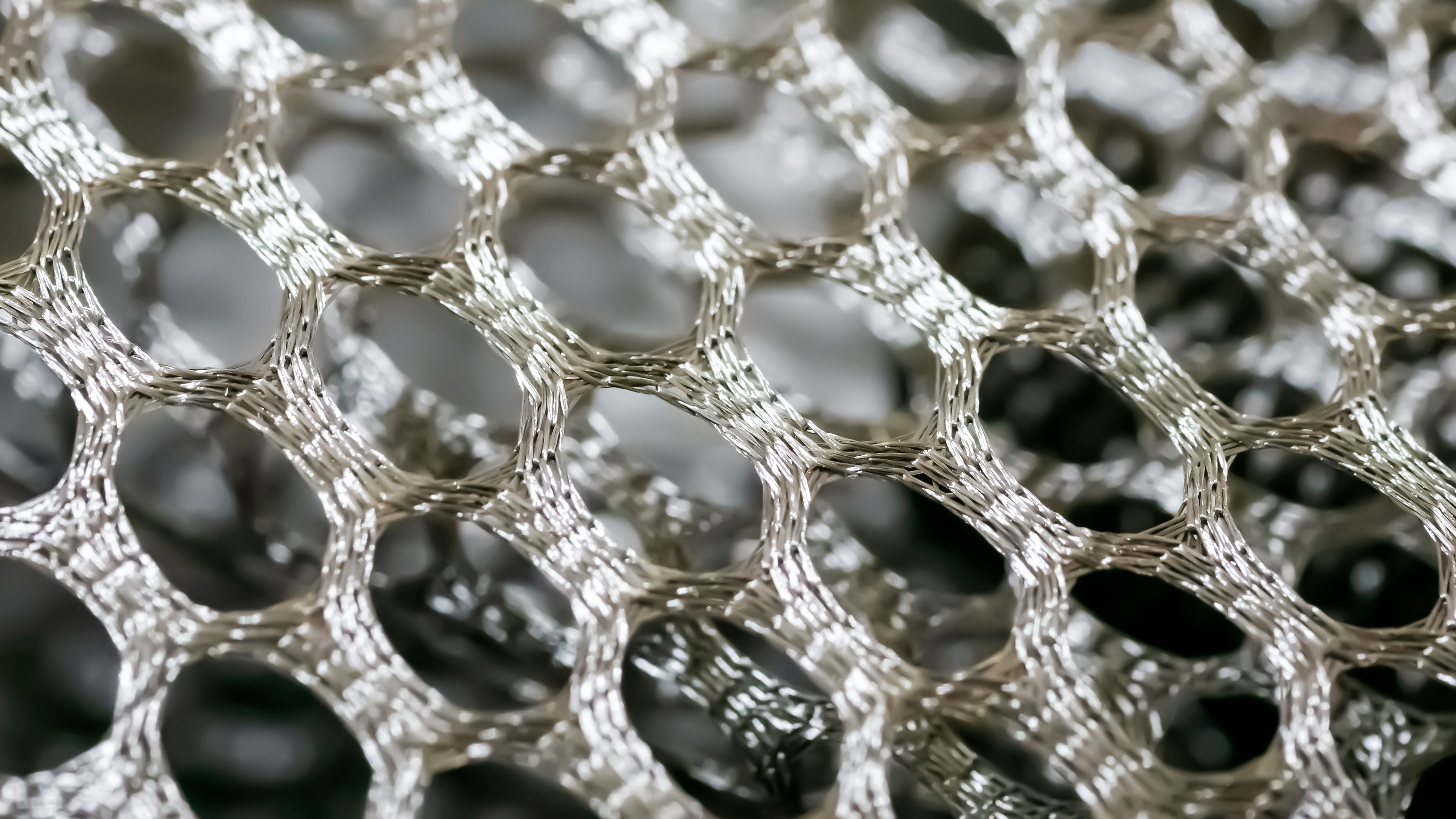

Metal Recycling

→

→

→

→

Metal recycling starts with collecting items like cans, appliances, and old machinery. At recycling plants, magnetic separation distinguishes ferrous (iron/steel) from non-ferrous (aluminum, copper) metals. Metals are cleaned, stripped of non-metal parts, and shredded.

The shredded metal is melted in high-temperature furnaces. Impurities are removed, and the pure molten metal is poured into molds to form ingots or sheets. These are then used to manufacture new products. Since metals can be recycled infinitely without quality loss, this process saves massive amounts of energy and raw materials.

Metal recycled materials

Plastic Recycling

→

→

→

→

Plastics are collected from bins or recycling centers and sorted by resin type using optical scanners and manual labor. Labels, caps, and other contaminants are removed. Clean plastics are then shredded into small flakes.

The flakes are melted and reformed into plastic pellets. These are sold to manufacturers to produce new bottles, containers, textiles, and more. Some plastics that can’t be mechanically recycled are broken down chemically into basic ingredients for reuse. Plastic recycling reduces petroleum use and helps manage long-lasting waste.

Recycled Plastic materials